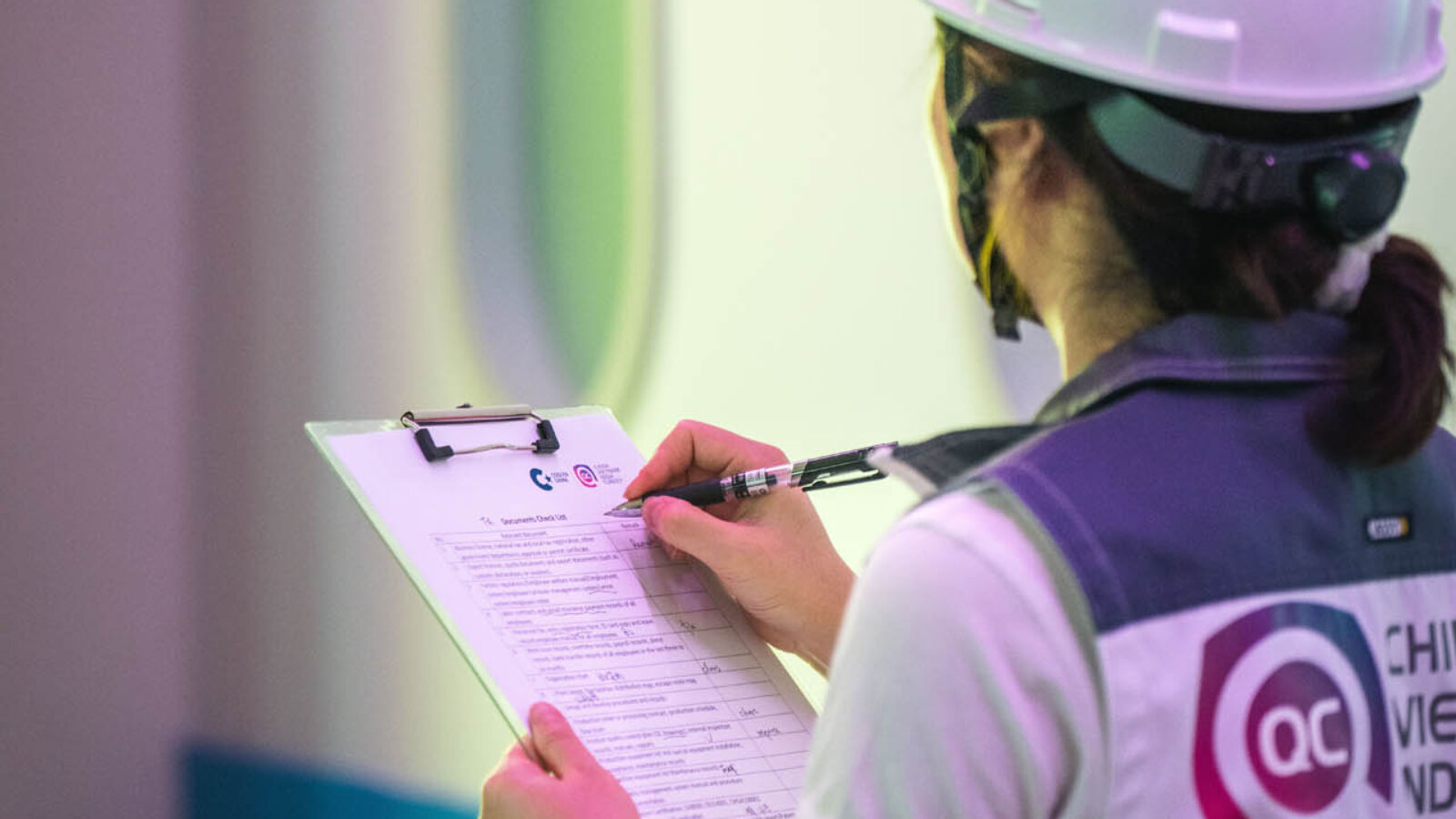

During Production Check

An During Production Check (DPC) detects quality defects at an early stage. This gives you as importer enough time to take appropriate measures and the production line functions optimally.

Quality Control performs comprehensive custom inspections and factory audits. We do this through a personalized approach based on your specific needs and requests as an importer.

Our comprehensive support is a customized service for Western companies and importers. Through customization and fulfillment of specific issues, even the most complicated problems in the supply chain can be avoided.

The improvement of the production process and the creation of long-term relationships between importers and suppliers are our priorities. Here we also pay close attention to customer needs, which we match with the scope of the project, the level of involvement, and the expected results.

Custom inspections provide comprehensive support for requests that differ from the usual inspections. This personalized approach gives you as an importer unique capabilities such as:

“We were having a quality issue with one of our Chinese suppliers, after Quality Control’s help we got a better handle on the quality issues we had.”

When fulfilling specific inspection or audit requirements, local representation of importers is very important. Without this representation, it is difficult to guarantee the desired quality of orders.

Customized inspections offer you as an importer with unique product specifications, and detailed advice, without having to be on-site yourself to do so. This allows you to take immediate remedial action on even the most complicated problems in the supply chain.

An During Production Check (DPC) detects quality defects at an early stage. This gives you as importer enough time to take appropriate measures and the production line functions optimally.

With a Container Loading Check (CLC), we monitor the loading process. This ensures that your orders are not unnecessarily delayed and that they reach their destination damage-free.

A First Article Inspection (FAI) clarifies whether the manufacturing process meets your desired specifications. As an importer, the inspection of the first article is important in assessing product quality.

A Pre-Shipment Inspection (PSI) is a final inspection before shipment. We assess the quality of products before they enter the container and are shipped.