Factory Audit

With the Factory Audit, we thoroughly screen the factory. For example, on quality, hygiene, working conditions and environment. This helps you as an importer to assess the supplier.

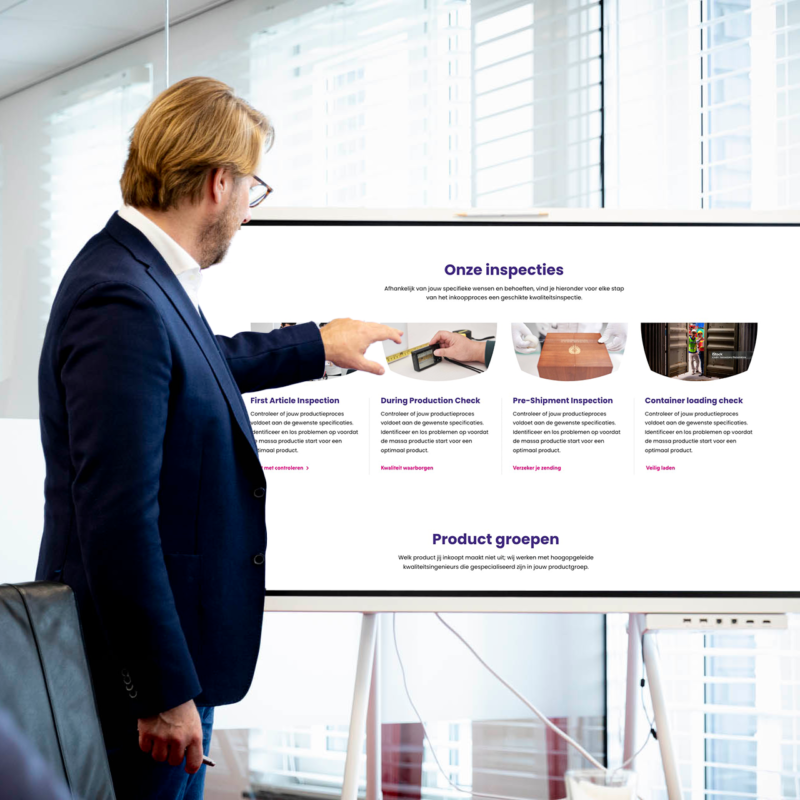

A Pre-Shipment Inspection is a final inspection before shipment. It assesses the quality of products before they are loaded into the container.

A Pre-Shipment Inspection reduces all kinds of risks for importers and is performed when approximately 80% to 100% of the total order has been produced and at least 80% of that has been packaged.

Thus, importers need to check the quality of each order before it is shipped to its destination. Therefore, the purpose of a final inspection before shipment is:

A pre-shipment inspection ensures that the quality of each order is and remains as desired.

A pre-shipment final inspection allows you to take remedial measures before the products are loaded and shipped and the production process is complete. This minimizes your risks and avoids downside risks.

Proper implementation of a PSI requires a lot of knowledge, time, and energy. Time that many companies/importers cannot spare. That is why they have their Pre-Shipment Inspections performed by an external quality control company.

Quality Control has a wide network in the world’s leading manufacturing countries. We, therefore, offer various other quality inspections in China, Vietnam, India, Pakistan, and Turkey in addition to Pre-Shipment Inspections. Find out more about the rest of our specializations here:

With the Factory Audit, we thoroughly screen the factory. For example, on quality, hygiene, working conditions and environment. This helps you as an importer to assess the supplier.

A First Article Inspection (FAI) clarifies whether the manufacturing process meets your desired specifications. As an importer, the inspection of the first article is important in assessing product quality.

With a Container Loading Check (CLC), we monitor the loading process. This ensures that your orders are not unnecessarily delayed and that they reach their destination damage-free.

An During Production Check (DPC) detects quality defects at an early stage. This gives you as importer enough time to take appropriate measures and the production line functions optimally.