Supply chain management during Chinese New Year 2024

Supply chain management during Chinese New Year 2024 The Chinese New Year in 2024 will pose challenges for Western importers and entrepreneurs. However, with careful..

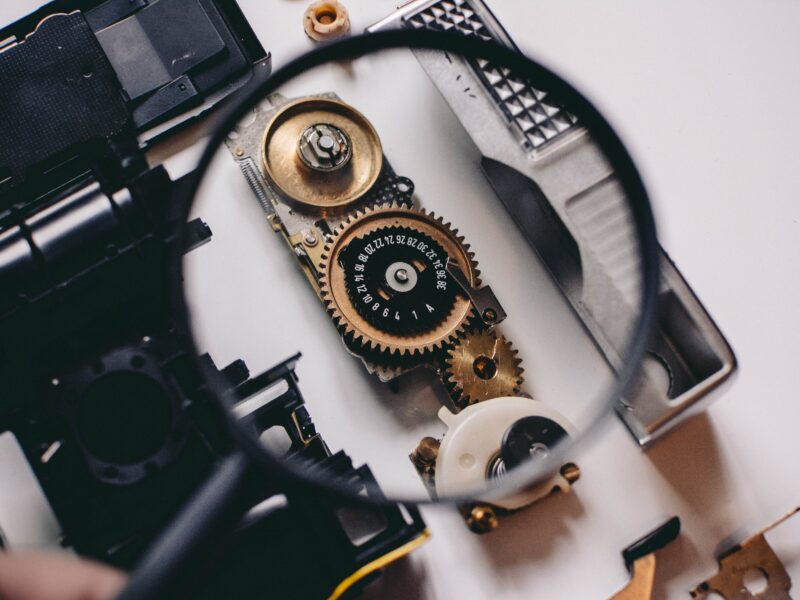

ou might be wondering: ‘Why would I need quality control?’ The answer has to do with the risks that importers face. These risks emerge because of the many ‘transfer moments.’ These are the moments in which the products and components are moved from intermediary to intermediary before the end product is delivered to the client. It is like the game you used to play when you were young, where a sentence was whispered from person to person to end up as something completely different at the end of the line. If those transfer moments add up, you want to be sure that your supplier understood your wishes. And how closing are your agreements? Will you get what you have ordered? And will your client receive the promised products? There are many possible problems you could face.

Our experience, for instance, is that factories will make concessions at the end of the production or in a repeat order. The reason for this that the factory is trying to save money by using cheaper materials, to pay less attention to quality, to use cheaper (less qualified) personnel, and to rush the production.

The average personnel turnover in companies is quite high. If there are new employees working on your products again and again, problems with repeat orders will arise. What wasn’t a problem last time, might be a problem next time. There is no such thing as a learning curve, in which the production process goes smoother and smoother because the factory learns from its mistakes. Quite contrary, with every new order, new problems arise, because many workers see your product for the first time. Those kind of problems make that quality control is a must.

Yet another problem is the costs attached to the process of importing. Shipping goods to Europe is a costly activity. Shipping defective or wrong goods back to China, India or Vietnam is not even an option. But, you know your way and your business is successful, and in the course of the years you have found suppliers with which you are happy. Every now and then you travel to different countries and make your rounds. It is not strange to think that next shipments will be good if the last were. On top of that, inspecting quality yourself is costly and time consuming. You have to be at other places, traveling is exhausting, you would make long days at the factory, and the traveling expenses are high. Also, you would like to plan the trip in time, but for some reason your production is delayed. So you stop inspecting at a certain point.

Unless you have the time and expertise to check on your factory and inspect the goods before shipment, it is a wise move to have someone else perform the quality control of your products. Professional and independent inspectors from experienced Quality Control companies offer the solution.